Noise, vibration, and harshness (NVH) are critical performance indicators in modern electric machines. Whether in automotive traction motors, industrial drives, or household appliances, customers expect smooth and quiet operation. Engineers have found that much of NVH originates in the active magnetic parts of a machine—the stator and rotor. By optimizing how these parts are built, especially through advanced lamination and stacking methods, manufacturers can dramatically lower NVH levels while maintaining efficiency and reliability.

Understanding NVH Sources in Electric Machines

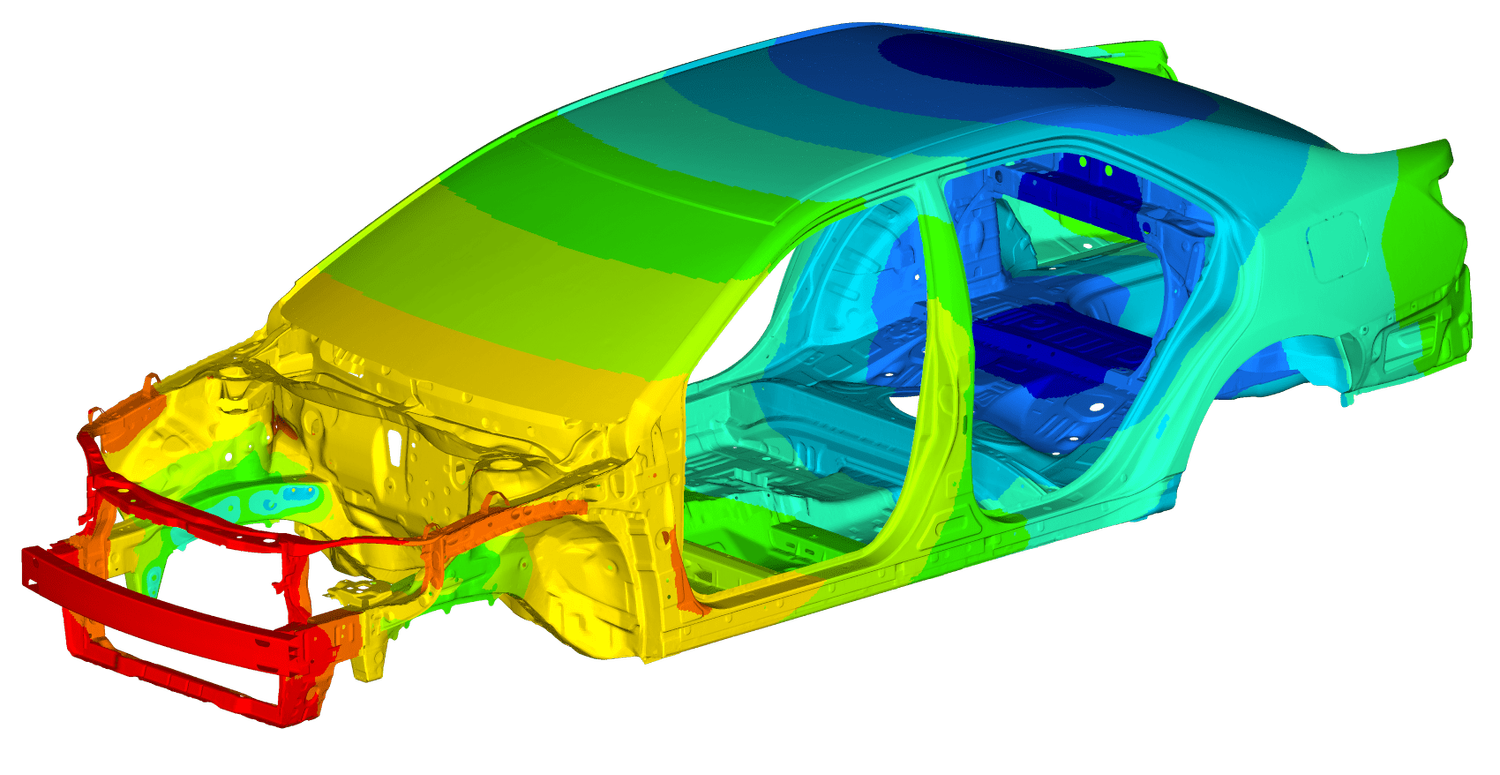

NVH issues in electric machines are multifaceted. Electromagnetic forces create radial and tangential vibrations as magnetic fields interact between the stator and rotor. Mechanical imbalances in shafts, bearings, or laminations amplify these vibrations. Meanwhile, structural resonances in housings and frames can transmit or even magnify unwanted noise. In high-speed traction motors, tonal noise from electromagnetic harmonics can be particularly noticeable.

Traditional NVH countermeasures—such as damping materials, rigid housings, or isolation mounts—help but add weight, cost, or complexity. A more fundamental solution lies in addressing the source of vibration itself: the magnetic circuit formed by stator and rotor stacks.

The Importance of Stator and Rotor Stacks

The stator and rotor stacks form the backbone of any electric machine. Built from thin electrical steel sheets, they guide magnetic flux, carry windings or magnets, and determine torque density. Their geometry and construction influence not only efficiency but also NVH performance. When properly designed, these stacks reduce force harmonics, suppress resonance, and minimize structural amplification of noise.

Key characteristics that affect NVH include:

- Lamination thickness: Thinner laminations reduce eddy current losses but also influence the stiffness and damping of the stack, impacting vibration modes.

- Stack length and geometry: Longer stacks change axial modes and can shift resonance frequencies out of the audible range.

- Assembly quality: Poorly bonded laminations may rattle under magnetic forces, generating tonal or broadband noise.

- Magnetic symmetry: Careful rotor slot design and stator winding layout reduce unbalanced magnetic pull, lowering vibration.

By refining these elements, engineers can achieve quieter, smoother machines.

Stator and Rotor Laminations as NVH Enablers

Modern stator and rotor laminations are more than just energy-efficiency tools; they are NVH enablers. Advances in laser cutting, stamping, and bonding allow precise control of lamination shape and consistency. For example, skewing laminations—slightly offsetting successive sheets—spreads harmonic forces over time, reducing tonal noise. Bonded laminations eliminate inter-sheet movement, removing the “buzz” that can occur when sheets vibrate against each other.

Material choice is equally important. High-grade electrical steels with tailored magnetic properties can minimize magnetostriction, a key contributor to audible noise. Some manufacturers also introduce thin coatings between laminations that not only insulate electrically but also damp mechanical vibrations.

Case Example: Automotive Traction Motors

Consider a traction motor for an electric vehicle. Customers demand a quiet cabin experience, yet the motor operates at high speed with rapid torque changes. Engineers discovered that electromagnetic forces from slot harmonics in the stator and rotor were exciting structural resonances near 1,200 Hz—well within the human audible range.

To mitigate this, they redesigned the stator and rotor stacks with skewed laminations, reducing harmonic alignment. They also adjusted lamination thickness to modify stiffness and shift resonance out of the problematic frequency range. Finally, adhesive bonding was applied to prevent inter-lamination vibration. The result was a reduction of motor tonal noise by over 8 dB(A), significantly improving perceived cabin comfort.

Integration with System-Level NVH Design

While the stator and rotor stacks play a central role, they are part of a larger NVH strategy. Engineers must consider:

- Housing design: A stiff, well-damped housing prevents amplification of lamination vibrations.

- Bearing quality: Imbalances or resonance in bearings can negate gains made in the stacks.

- Control algorithms: Advanced pulse-width modulation (PWM) strategies can minimize torque ripple, complementing mechanical improvements.

Thus, stack design must be integrated with mechanical, electrical, and control considerations for optimal results.

Future Directions

Research is advancing rapidly in this field. Additive manufacturing and novel bonding techniques promise even more precise control of stator and rotor laminations. Hybrid materials combining electrical steel with damping composites could suppress vibration at the source. Digital twin models now allow engineers to simulate NVH behavior across multiple domains before a prototype is ever built.

As electric mobility expands and quietness becomes a differentiator, the role of stator and rotor stacks in NVH reduction will only grow more significant. Manufacturers who invest in this area stand to gain not only performance benefits but also competitive advantage.

Conclusion

NVH is no longer just an afterthought in electric machine design—it is a central requirement. By focusing on the stator and rotor stacks, engineers can address NVH at its source. Optimized lamination thickness, skewing, bonding, and material selection allow machines to operate more quietly and smoothly. Whether in automotive traction motors, industrial drives, or consumer products, well-designed stator and rotor laminations provide a cost-effective, durable path to NVH reduction. For businesses and customers alike, the payoff is clear: quieter, more efficient, and more reliable machines.